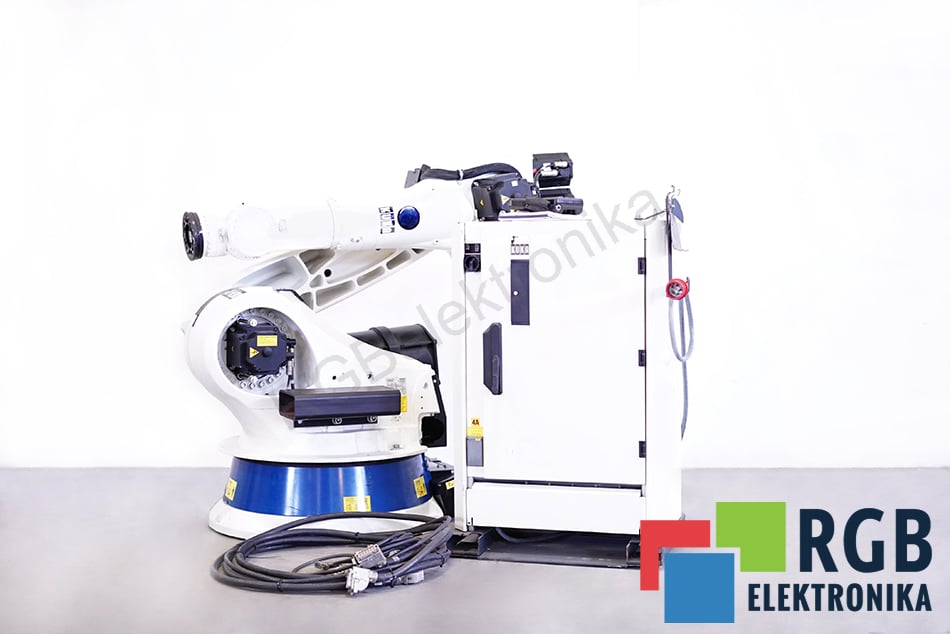

INDUSTRIAL ROBOT KR2150 KUKA

- Product condition: used

- Fully tested and cleaned

- Warranty: no warranty

- Dedicated courier: yes

Related Products

KR2150 KUKA

WIDE OFFER OF INDUSTRIAL WORKS ADAPTED TO YOUR NEEDS!

All our work comes from European factories where they were regularly serviced and underwent detailed inspections.

Our robots are 100% efficient - each robot is started and undergoes tests under load.

The test consists of min. execution of all axes and robot work in automatic cycle.

Each of the robots prior to sale is subjected to a general review consisting of: refinish coating, lubricant replacement and peripheral testing (control cabinet, teach pendant).

On request we secure the stock of spare parts for robots - in case of failure parts will arrive in 24h!

Parameters

| Reach (mm) | - |

| Payload (kg) | - |

| Year of production | - |

| The application from which the robot originated | Welding, varnishing |

| Number of hours worked (h) | - |

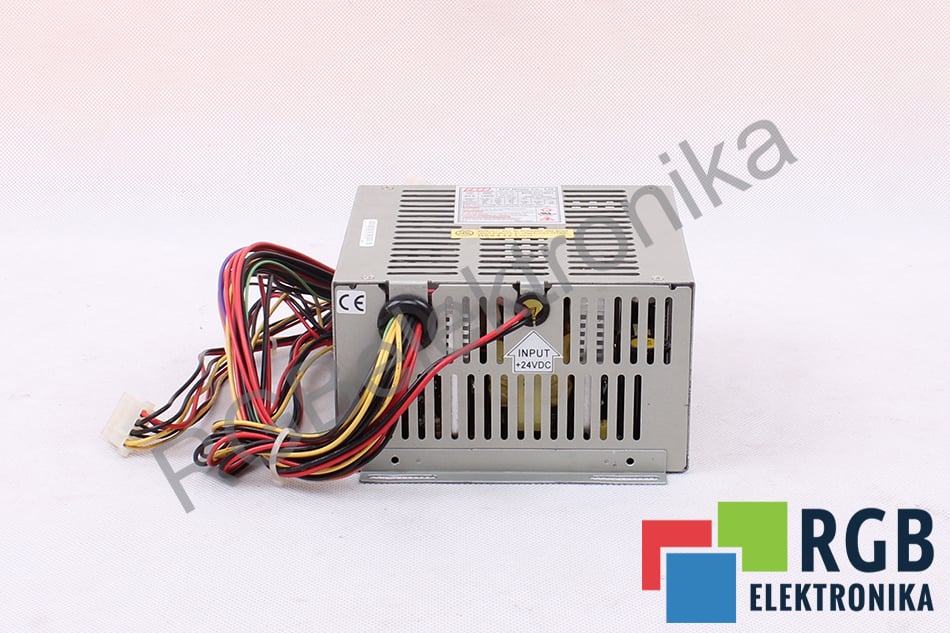

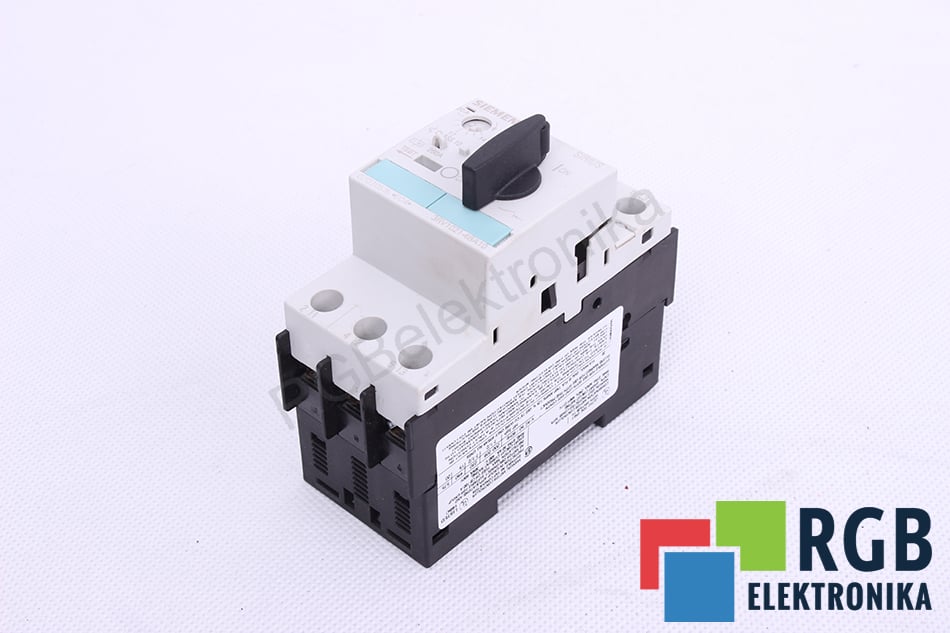

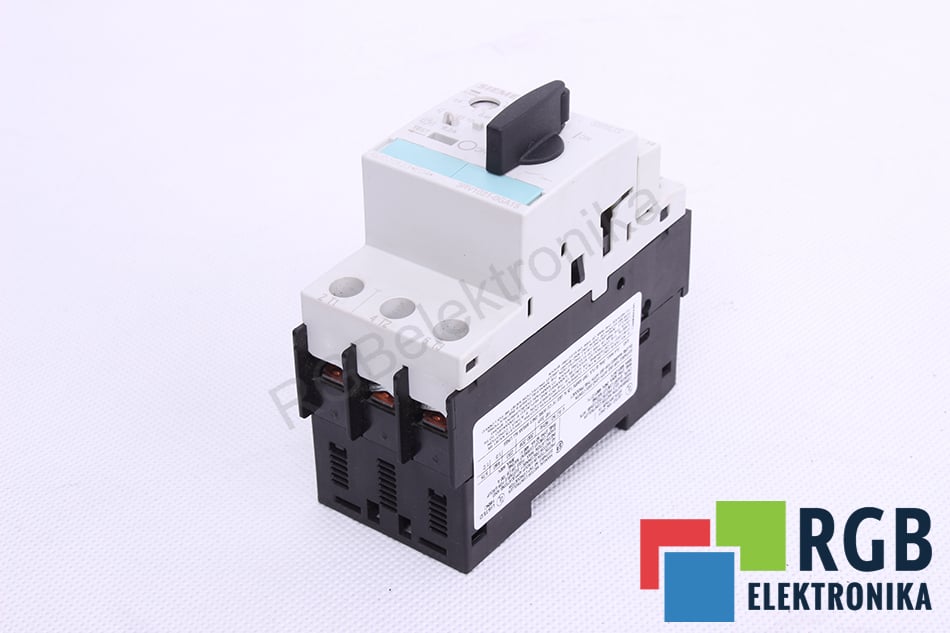

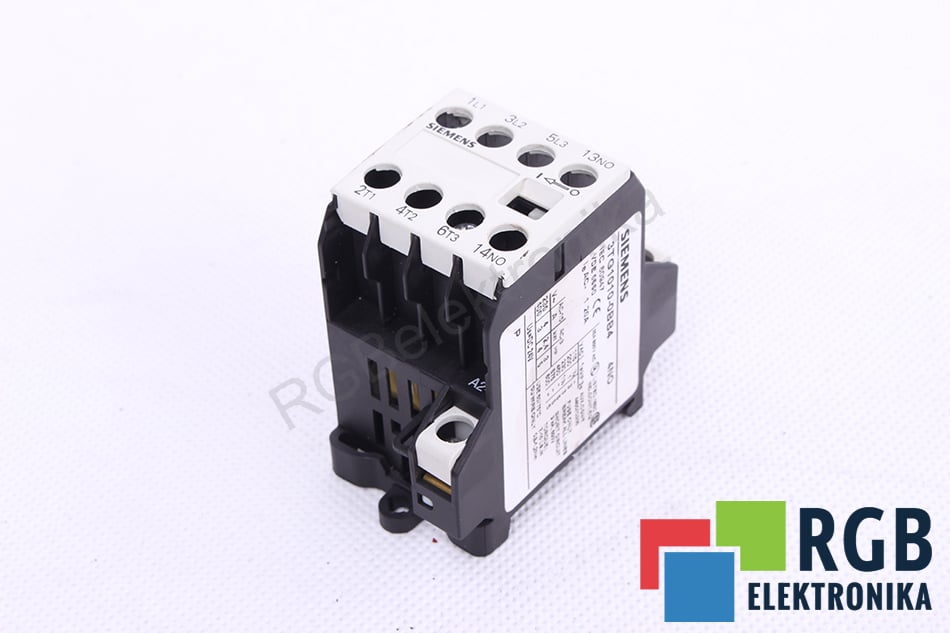

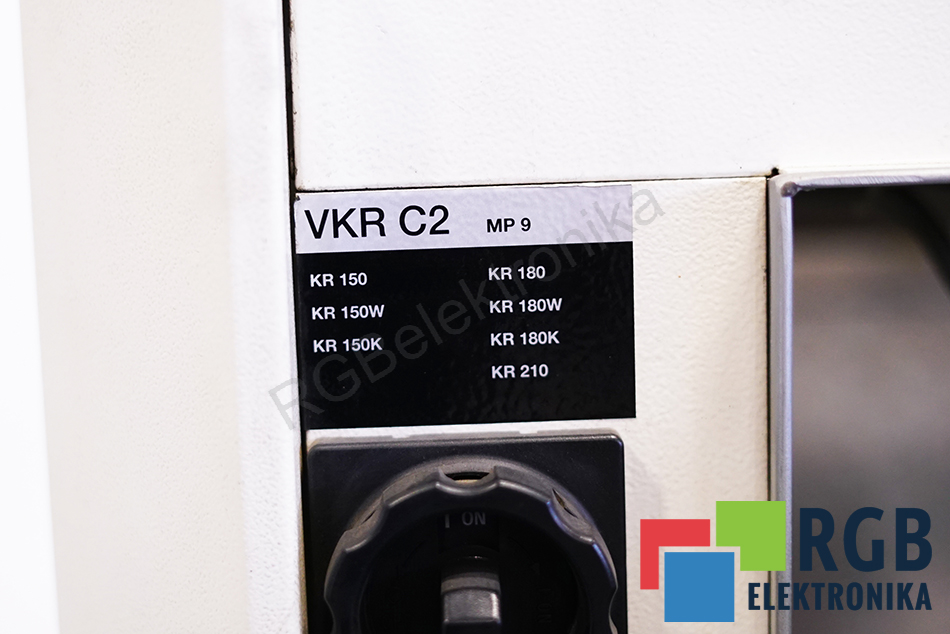

| Tooling robot | Robot control cabinet with controller |

| Wiring | Complete wiring |

| Technical Documentation | Complete technical documentation, user manual and programming |

Applications of robots

- WELDING INDUSTRIAL ROBOTS: https://youtu.be/_3AXcZaEbPw

- OPERATE EDGE PRASS: https://youtu.be/Nrea-6JYXmM

- COLLECTION AND REMOVAL OF ELEMENTS: https://youtu.be/nkLd45Ftfhc

- PALLETIZATION AND PACKAGING: https://youtu.be/7U1-X5ogsKA

- LACQUERED WITH INDUSTRIAL ROBOT: https://youtu.be/fqMP6WX2o-g

- METAL PROCESSING, GRINDING, MILLING, DEBURRING: https://youtu.be/7sp3r_GtkAw

- POINT WELDING: https://youtu.be/N5AYZxsnDuM

Robot integration / programming

We design, execute and implement robotic stations. These stations are used most often in production processes at the packaging and palletising stage, but also in the assembly, transport or placement and removal of items from the processing machines.

We are able to design and execute according to customer needs a complete robotic stand (robotic). It consists of appropriately selected and programmed robot, gripper, complete safety system, operator panel and other required components.

- Weight [kg] 100.0000

- Model KR2150

- Year of production -

- Robot payload [kg] -

- Robot reach [mm] -

- Worked hours [h] -

Choose

Choose